Pitot tube flow meters are ideally suited to wet, dirty and high velocity compressed air and gas systems that contain some level of contamination. This makes a pitot tube flow meter ideal for measuring flow, temperature and pressure near the outlet of compressors and other difficult environments.

Pitot tube flow meters have no moving parts, a low pressure drop and are vibration proof. The integrated pressure and temperature sensors give real-time monitoring of fluid pressure and temperature. The sensor has an extremely sensitive differential pressure measurement that allows pitot tube flow meters to be used over a wide flow range, whilst the patented anti-condensation technology ensures the sensor can be used under 100% saturated conditions. The flow meter can be easily installed under pressure through a 1/2″ ball valve.

Innovative online auto-calibration technology compensates for temperature and pressure changes, enabling the pitot tube flow meter to perform stable accurate measurements for years to come.

Important

- You need to maintain a minimum flow velocity of 5 Nm/s (17 ft/s) for the pitot tube to work correctly. Below this minimum velocity, the flow meter reading will be zero.

- Flow meters must be installed away from bends, edges, seams, changes in pipe size and other obstructions

- Incorrect wiring or installation can give false readings, damage the sensor and void the warranty. If you aren’t sure how to install or wire the sensor, please contact us. Full installation and wiring instructions are available in the User Manual.

Pitot Tube Flow Meter Pack

- Pitot Tube Flow Meter

- M12 connector (data cable optional)

- Calibration certificate

- User Manual

- 12 month warranty

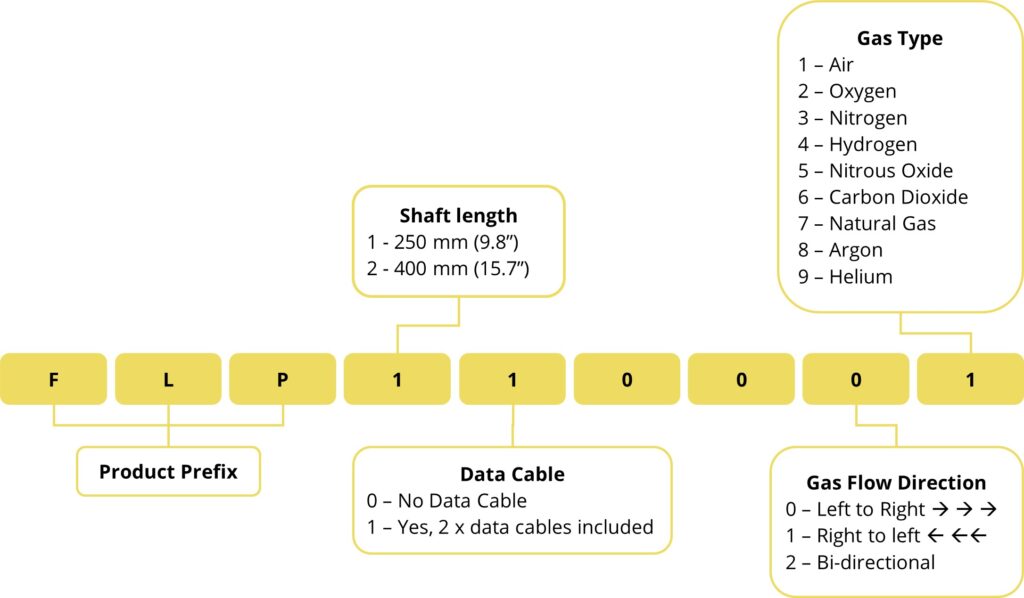

Pitot Tube Flow Meter Options

- Two shaft length options: 250 mm (9.8″) or 400 mm (15.7″)

- Multiple gas options: Air, Argon, Carbon Dioxide, Helium, Hydrogen, Natural Gas, Nitrogen, Nitrous Oxide and Oxygen

Warranty & Calibration

12 month warranty

Calibration is recommended every 2 years (provided the sensor is not exposed to relative humidity above 85%).

Annual calibration is required if the sensor is exposed to relative humidity above 85%.

Accessories

Accessories such as mechanical and electrical fittings are available on the Accessories page.

Other Information

Part Numbers: FLP100001, FLP200001, FLP110001, FLP210001, FLP110011, FLP210011,FLP110021, FLP210021